Corpo

Projeto

Padrão

Pistola de pulverização

Peso

Projeto

Pulverizando o casaco transparente

Atomização

Corpo

Projeto

Padrão

Pistola de pulverização

Peso

Projeto

Pulverizando o casaco transparente

Atomização

PHS-156 HVLP Spray Gun

Pistola de pulverização para todos os fins

Atualizações populares

Mais acessórios

Corpo

Projeto

Padrão

Pistola de pulverização

Peso

Projeto

Pulverizando o casaco transparente

Atomização

Em estoque! Navios dentro de 1 dia útil.

Garantia de 1 ano

Entrega rápida dentro de 5-8 dias úteis

Detalhes gratuitos de devoluções de 60 dias

PHS-156 HVLP Spray Gun

Se tiver alguma dúvida, entre em contato conosco. Responderemos o mais breve possível, em até 24 horas, durante a semana.

-

Informações de envio

Use este texto para responder às perguntas dos seus clientes com o máximo de detalhes possível.

-

Suporte ao cliente

Use este texto para responder às perguntas dos seus clientes com o máximo de detalhes possível.

-

FAQs

Use este texto para responder às perguntas dos seus clientes com o máximo de detalhes possível.

-

Contate-nos

Use este texto para responder às perguntas dos seus clientes com o máximo de detalhes possível.

Por que PHS-156?

A pistola de pulverização PHS-156 integra Tecnologia HVLP (Alto Volume e Baixa Pressão) com Otimização inteligente da dinâmica de fluidos, proporcionando desempenho excepcional para aplicações de revestimento industrial e de precisão. Seu avançado sistema de atomização minimiza o desperdício de excesso de tinta por meio de sinergia de baixa pressão e alto volume, garantindo acabamentos perfeitamente uniformes, ideais para repintura automotiva, acabamento de madeira e tratamentos de substratos metálicos.

Revisão do pintor

Porphis PHS156 HVLP Low Air Consumption Base Coat Spray Gun

Porphis 717 Revisão: a melhor arma de pintura orçamentária para Au impecável

PORPHIS PRD 717 1.3 A melhor pistola de pulverização de baixa pressão?

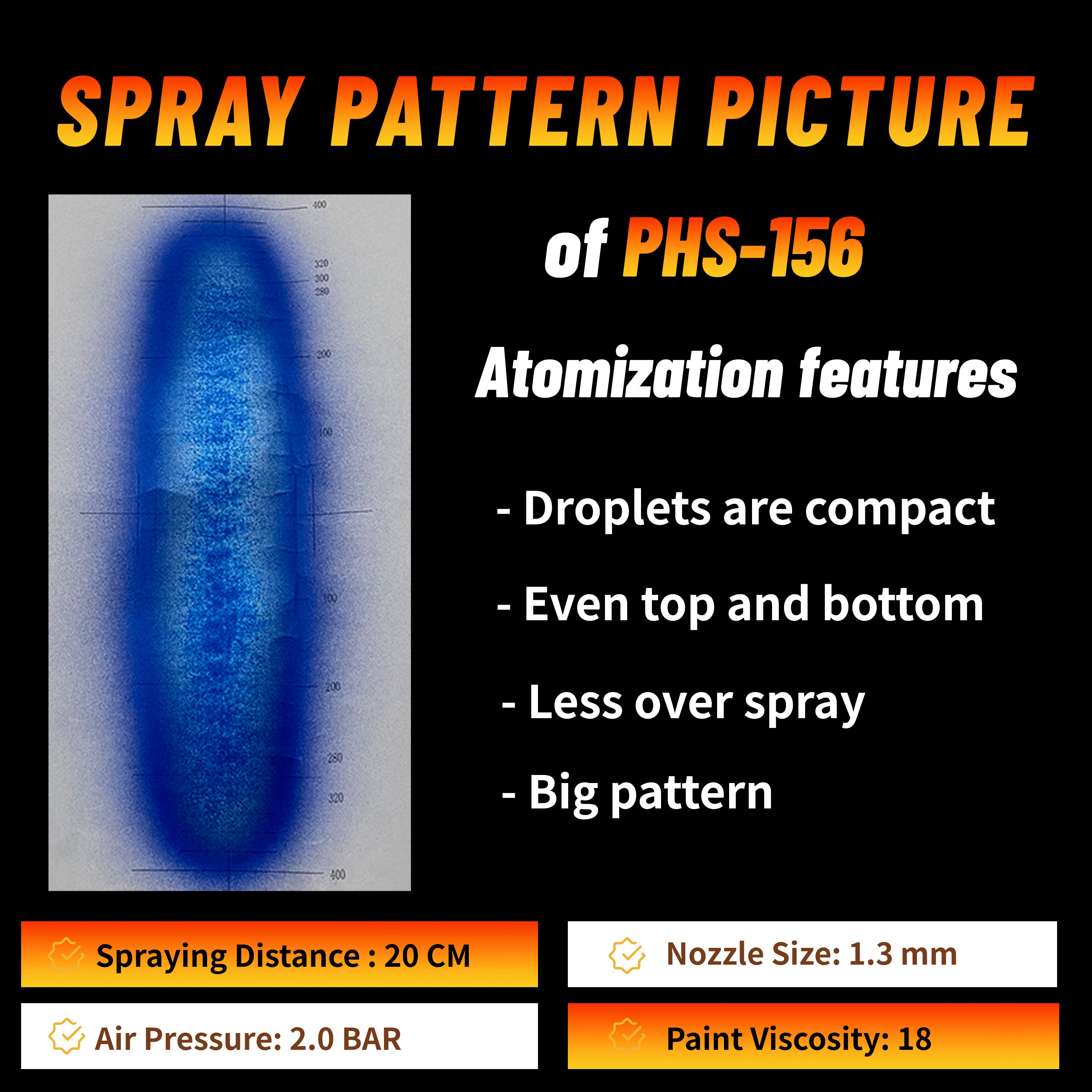

Atomização uniforme

A pistola de pulverização PHS-156 utiliza a tecnologia de sinergia de fluxo de ar dinâmico para obter uma distribuição de gotas altamente uniforme e compacta, garantindo uma cobertura excepcional de cima para baixo. A uma distância padrão de pulverização de 20 cm, gera um padrão de pulverização amplo e estável em forma de leque, reduzindo drasticamente o excesso de tinta e aumentando a eficiência de adesão da tinta. O sistema de atomização é otimizado para superfícies geométricas complexas — sejam curvas, angulares ou irregulares — garantindo acabamentos perfeitamente lisos, sem escorrimentos ou imperfeições de textura.

Módulo de Atomização de Baixa Turbulência

Tecnologia do bico HVLP

Bico para Pistola de Pulverização PHS-156: Design de Tripla Eficiência, Redefinindo o Desempenho do Revestimento. O bico para pistola de pulverização PHS-156 possui uma estrutura de canal de fluxo de precisão multiestágios e tecnologia de estrangulamento inteligente, aliada a um design de canal de nível micrométrico, para obter controle preciso do material e distribuição de gotas ultrafina e uniforme. Seu perfil geométrico inovador reduz a dispersão da tinta em 40%, enquanto o amplo padrão de pulverização em leque permite uma cobertura rápida de áreas maiores, aumentando a eficiência operacional em 35%. O material composto resistente ao desgaste e o revestimento antientupimento do bico garantem uma atomização estável, evitando o acúmulo de partículas ou a distorção do padrão de pulverização.

Economize tinta

Design integrado

A pistola de pulverização PHS-156 conta com uma arquitetura integrada inteligente, otimizando a dinâmica do fluxo de ar interno por meio de um projeto biomimético da trajetória do fluido para reduzir drasticamente a resistência à pulverização, garantindo uma distribuição eficiente e estável do material, minimizando a perda de energia. O corpo da pistola utiliza tecnologia de proteção composta multicamadas, combinando estruturas resistentes a impactos com revestimentos adaptáveis para suportar temperaturas extremas, corrosão química e operações de alta frequência, mantendo um desempenho consistente ao longo do tempo.

Sem anel de distribuição

Especificações de tecnologia

Especificação

Materiais e processos

Incluído na caixa

600 ml de copo branco

Manual

Kit de serviço

Pistola de pulverização

Perguntas frequentes - PHS-156

Qual é a faixa de pressão para usar a pistola de pulverização PHS-156?

A pistola de pulverização PHS-156 é uma pistola de pulverização de baixa pressão com uma faixa de pressão de 1,6-2,0 bar.

Qual versão de pintura de versão 2.0 conector de copo é adequada para pistola de pulverização PHS-156?

O tamanho da rosca do canal de tinta PHS-156 é Fêmea M16 * 1,5, e você pode escolher o conector do copo de mistura de tinta versão 2.0 apropriado com base nesse tamanho.

Que tinta o PHS-156 é adequado para pulverização?

Recomendado para pulverização de revestimentos de base.

Onde faço peças para reparo e substituição?

Você pode comprar diretamente nosso kit de reparo de peças para pistola de pulverização série PHS-15 para manutenção diária.

O PHS-156 salva tinta?

Devido ao bico HVLP transportado pelo PHS-156, ele economiza tinta.