Nozzle

Spray Gun

Fluid Adjustment Set

Air Distribution Ring

Weight

Design

Spraying Clear Coat

Atomization

Nozzle

Spray Gun

Fluid Adjustment Set

Air Distribution Ring

Weight

Design

Spraying Clear Coat

Atomization

ALL NEW PRD-817 1.3MM VS SPRAY GUN

Upgrade Parts

Breathing Protection

Nozzle

Spray Gun

Fluid Adjustment Set

Air Distribution Ring

Weight

Design

Spraying Clear Coat

Atomization

In stock! Ships within 1 business days.

1-Year Warranty

Free shipping and taxes

Delivered in 5 to 8 working days

ALL NEW PRD-817 1.3MM VS SPRAY GUN

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Discover PRD-817

Cutting-Edge Split Nozzle Atomization™ Technology

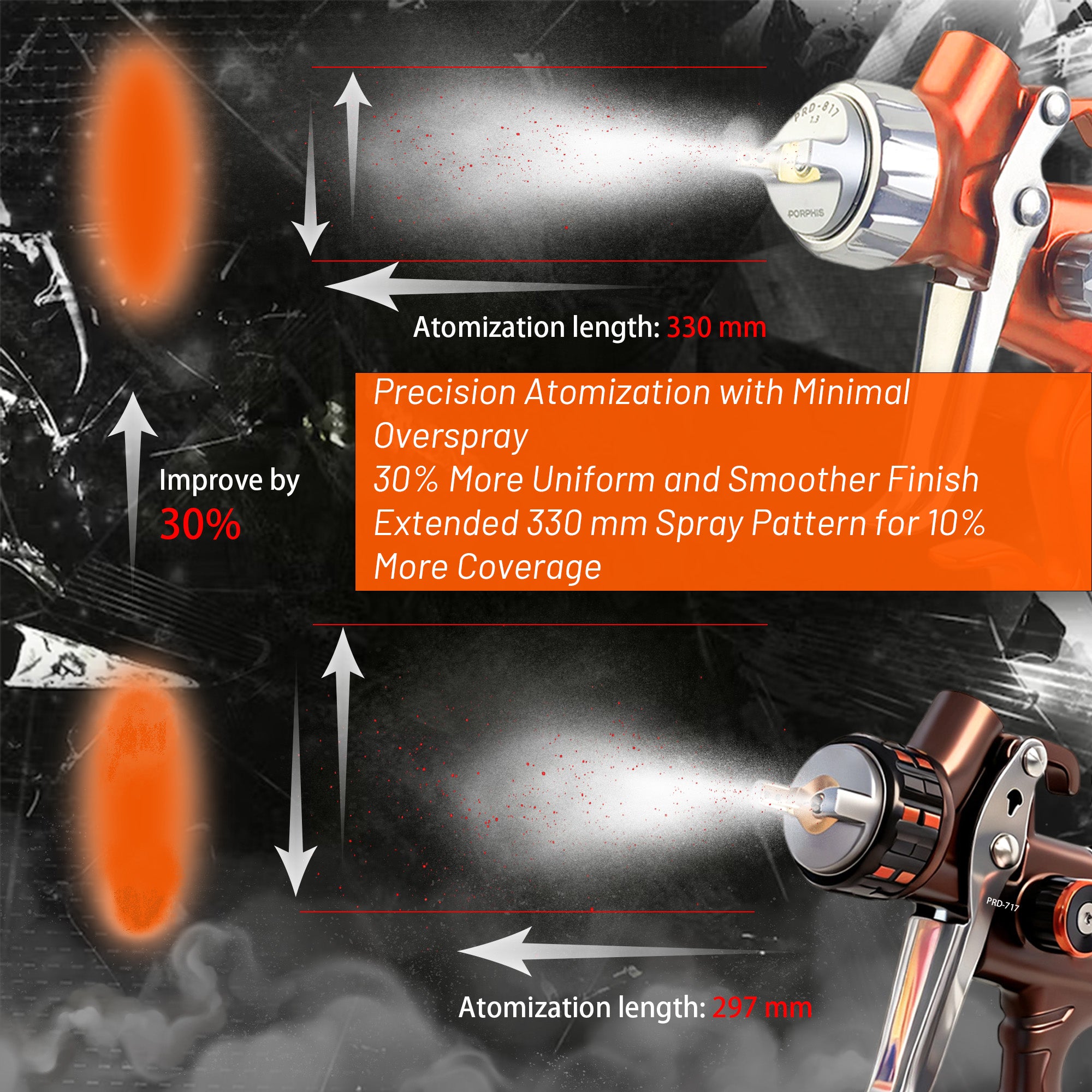

PRD-817 is dedicated to achieving precise atomization with minimal overspray. Through the application of cutting-edge technology, it not only delivers a 30% more uniform coating for a smoother, flawless finish on workpiece surfaces but also effectively controls paint waste, saving you costs.

Painter Review

Porphis PRD817 Spray Gun, Low Pressure, Low Overspray, Low Air Consumption V Tip PRD815

Why PRD-817?

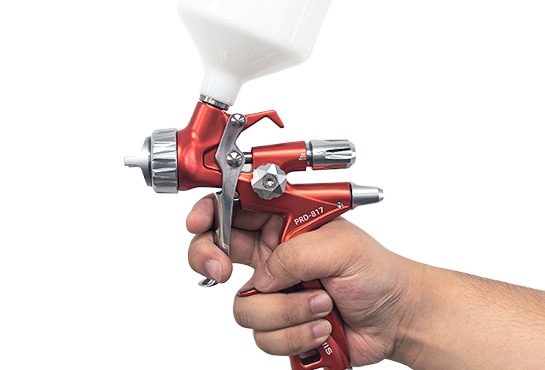

Our new-generation flagship pneumatic spray gun, the PRD-817, engineered to elevate your spraying process to new heights.

Its core breakthrough lies in achieving an extended atomization length of 330 mm.

Compared to the previous model, the PRD-717, this innovation directly results in a 10% increase in coverage, significantly boosting your efficiency for large-area applications.

What's more, the PRD-817 is dedicated to achieving precise atomization with minimal overspray.

Through the application of cutting-edge technology, it not only delivers a 30% more uniform coating for a smoother, flawless finish on workpiece surfaces but also effectively controls paint waste, saving you costs.

Choosing the PRD-817 means opting for greater efficiency, superior quality, and more economical operation.

Upgrade your spraying experience now and appreciate the perfect fusion of professionalism and precision engineering.

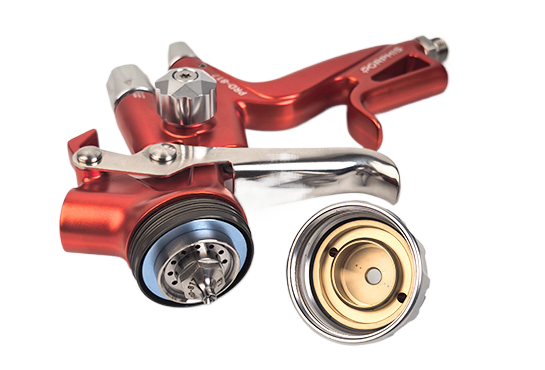

Integrated Turbulence Ring

The PRD-817 is engineered with a groundbreaking Integrated Turbulence Ring that revolutionizes airflow control.

This built-in innovation ensures consistently balanced air distribution from top to bottom, eliminating uneven pressure and turbulent spots.

By optimizing the air stream, it directly enhances split nozzle performance by approximately 15%, resulting in a supremely stable spray pattern, reduced pulsation, and flawless, predictable results on every project.

Experience the pinnacle of control and consistency—directly from the core of the PRD-817.

Enhances 15% split nozzle performance

Self-Cleaning Action

Meet the innovative Anti-Clog Air Cap, engineered to tackle residue buildup head-on.

Its intelligent structure features a self-cleaning action that actively helps prevent and clear blockages within the split nozzle, especially when working with demanding materials like clear coats.

This breakthrough significantly minimizes maintenance demand sand eliminates downtime, ensuring a smooth, uninterrupted workflow.

Focus on your craft, not on cleaning—PRD-817 keeps you spraying.

Anti-Clog Air Cap

Durable Multi-Layer Plasma Electrolytic Orange Coating

Crafted for both performance and presence, the PRD-817 features a striking and resilient orange finish achieved through an advanced plasma electrolytic coloring process.

This multi-layer protective coating is not only visually iconic but also engineered for extreme durability—highly resistant to chipping, scratches, and daily wear.

Beyond aesthetics, it ensures your tool maintains its professional look and integrity over time, even in demanding working environments.

Built to last, designed to stand out.

Plasma electrolytic coloring process

Tech Specs

Specification

Materials and Processes

Included in the Box

600ml white cup

Manual

Service kit

Spray gun

FAQs - PRD-817

What is the pressure range for using the PRD-817 spray gun?

The PRD-817 spray gun with a pressure range of 1.3-1.8 bar.

What 2.0 version paint mixing cup connector is suitable for PRD-817 spray gun?

The thread size of the PRD-817 paint channel is Male M16 * 1.5, and you can choose the appropriate 2.0 version paint mixing cup connector based on this size.

What paint is PRD-817 suitable for spraying?

Recommended for spraying clear&base coat system

What are the features of the all new PRD-817?

PRD-817 Spray Gun: Key Highlights & Advantages

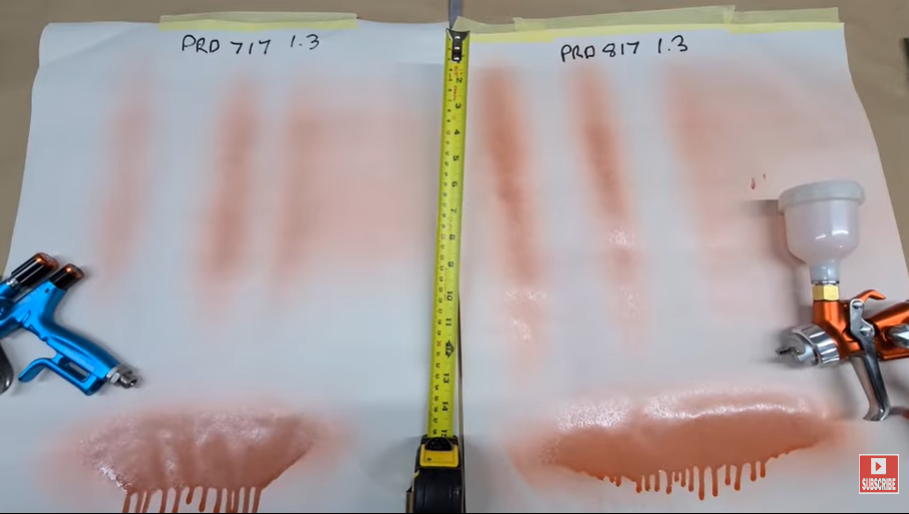

1、Precision Atomization with Nearly Vanishing Overspray

Experience a remarkably stable atomization process that drastically reduces overspray and paint scatter compared to the PRD-717. Achieve an overspray rate as low as ~1%—a 5% improvement—while boosting spraying efficiency and workspace cleanliness by 10%.

2、30% More Uniform Finish for Superior Smoothness

Benefit from a comprehensively optimized atomization pattern that delivers 30% more even coverage and a significantly finer finish, enabling professional-grade surface results with ease.

3、Extended 330mm Spray Pattern for 10% Greater Coverage

Gain more operational freedom with a 10% longer atomization distance than the PRD-717. This expanded range allows for greater working distance and significantly improved application efficiency.

4、Durable Multi-Layer Plasma Electrolytic Orange Coating

Featuring an advanced plasma electrolytic coloring process, the surface boasts a multi-layer protective finish. The iconic orange color is highly resistant to chipping and wear, ensuring long-lasting visual appeal.

5、30% Longer Service Life for Key Wear Components

Through a structural breakthrough in the "Dynamic Tolerance Zone" for the air cap and nozzle, the lifespan of these critical parts is extended by 30%, setting a new standard for durability.

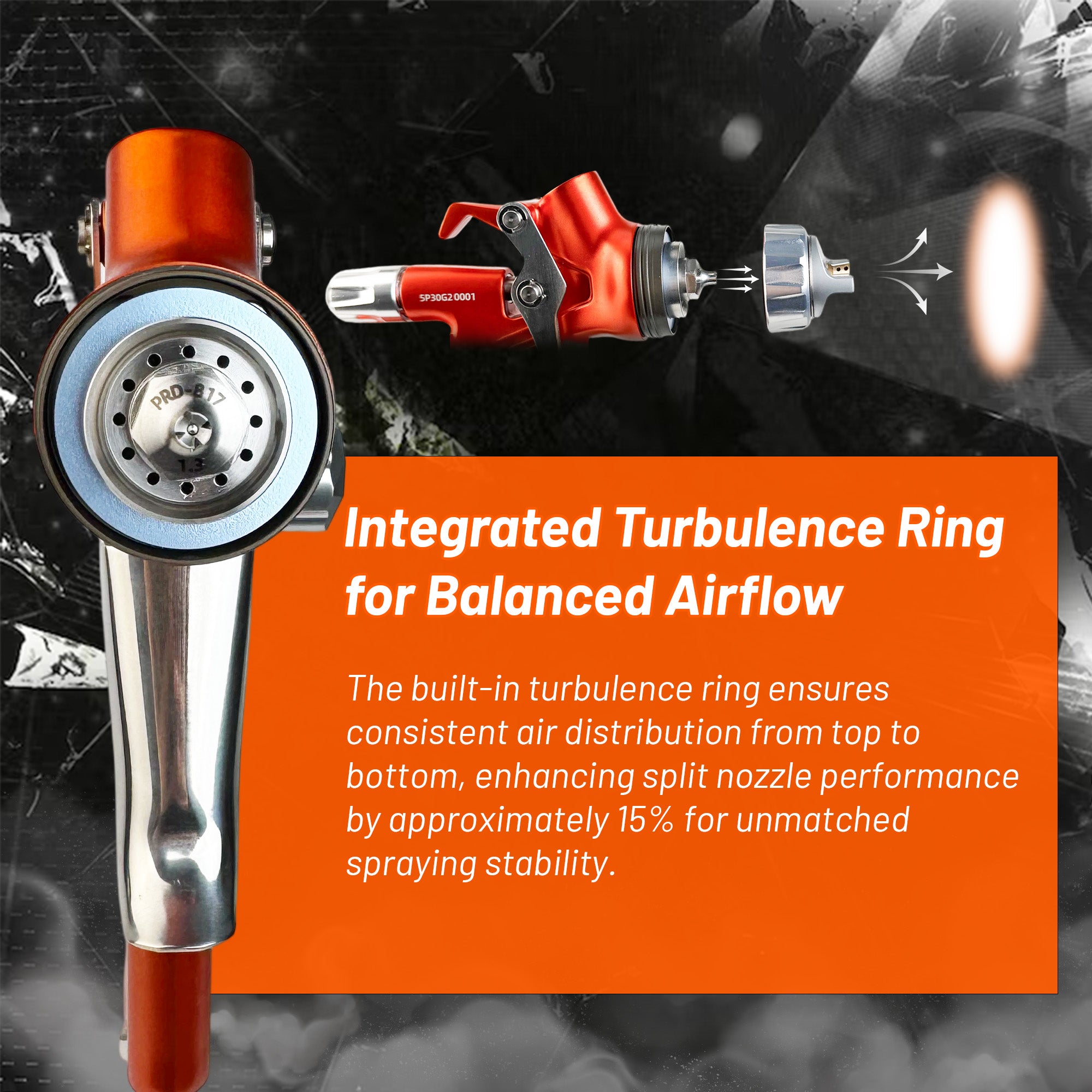

6、Integrated Turbulence Ring for Balanced Airflow

The built-in turbulence ring ensures consistent air distribution from top to bottom, enhancing split nozzle performance by approximately 15% for unmatched spraying stability.

7、Redesigned Anti-Clog Air Cap with Self-Cleaning Action

The newly engineered air cap structure actively helps prevent and clear residue buildup within the split nozzle. This is particularly effective for clear coats, minimizing maintenance and ensuring uninterrupted workflow.

Activity Rules

Event Deadline: 12/31/2025

Ranking is based on the order of reviews.

Review rewards will be mailed within 5 business days.

Discount codes will be sent via email.

Discount valid until 12/31/2025